Skip to contentK1-project: additive

K2-project:

K3-project:

K4-project:

- Projects »

Our additive projects:

K1-project: additive

"ICL-PS-LWC”

The aim of our K1 project was to develop and patent a solid admixture that significantly improves the compressive and flexural strength as well as other concrete technological properties of lightweight concretes with medium to high polystyrene beads.

Why is the use of lightweight polystyrene lightweight concrete more advantageous than that of conventional concretes? Because:

- … by using polystyrene beads as additives, structures with much better thermal conductivity and thermal insulation properties can be scaled and structural elements (block elements and masonry elements) can be made compared to conventional concretes.

- … the mechanical properties of the lightweight polystyrene lightweight concretes prepared with our admixture approach or exceed the mechanical properties of conventional concretes, for example compressive and flexural strength

- … using a combination of ICL-CA and ICL-technology, concretes with excellent waterproofing and fire resistance properties can be produced

Further professional information is provided in the following brochure, which can be downloaded in pdf format:

K2-project:

"ICL-Pad-LWC”

Our K2 project requires the development of admixtures and processes aimed at significantly reducing the aggregate content of normal (gravel) concretes and the use of various plastic wastes that can be replaced.

K3-project:

"ICL-Admix-LWC”

In the framework of the K3 project, we are working on the development of an additive that can be used to increase the compressive strength class of normal (gravel) concretes with the same cement and aggregate content.

K4-project:

"ICL-PSR-LWC” and "ICL-PR-LWC"

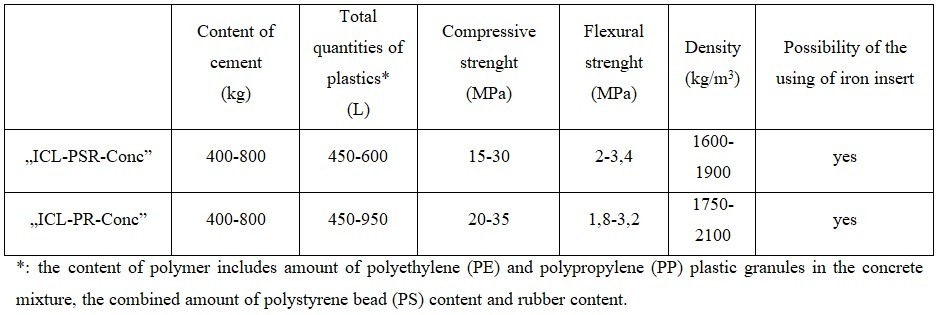

In the K4 project, our goal is to develop an additive that can be used to produce plastic granules (PP; PE), polystyrene bead waste (EPS) and rubber fragments of different sizes and compositions with high compressive and flexural strength, good thermal and sound insulation properties, and lightweight concretes with excellent watertightness and fire resistance properties, with a typical body density of 1600-2000 kg/m3.

In the name of the project and in the marking of the samples, the marking “PSR” (“Polymer-Styrene-Rubber”) refers to lightweight concrete produced with a mixture of plastic-polystyrene-bead rubber additives, the term “PR” (“Polymer-Rubber”) refers to concrete-admixtured concrete mixes.

The following table gives the typical data of the concrete mixtures under development: